Semi-Finished S/FTP CAT6 Lan Cable

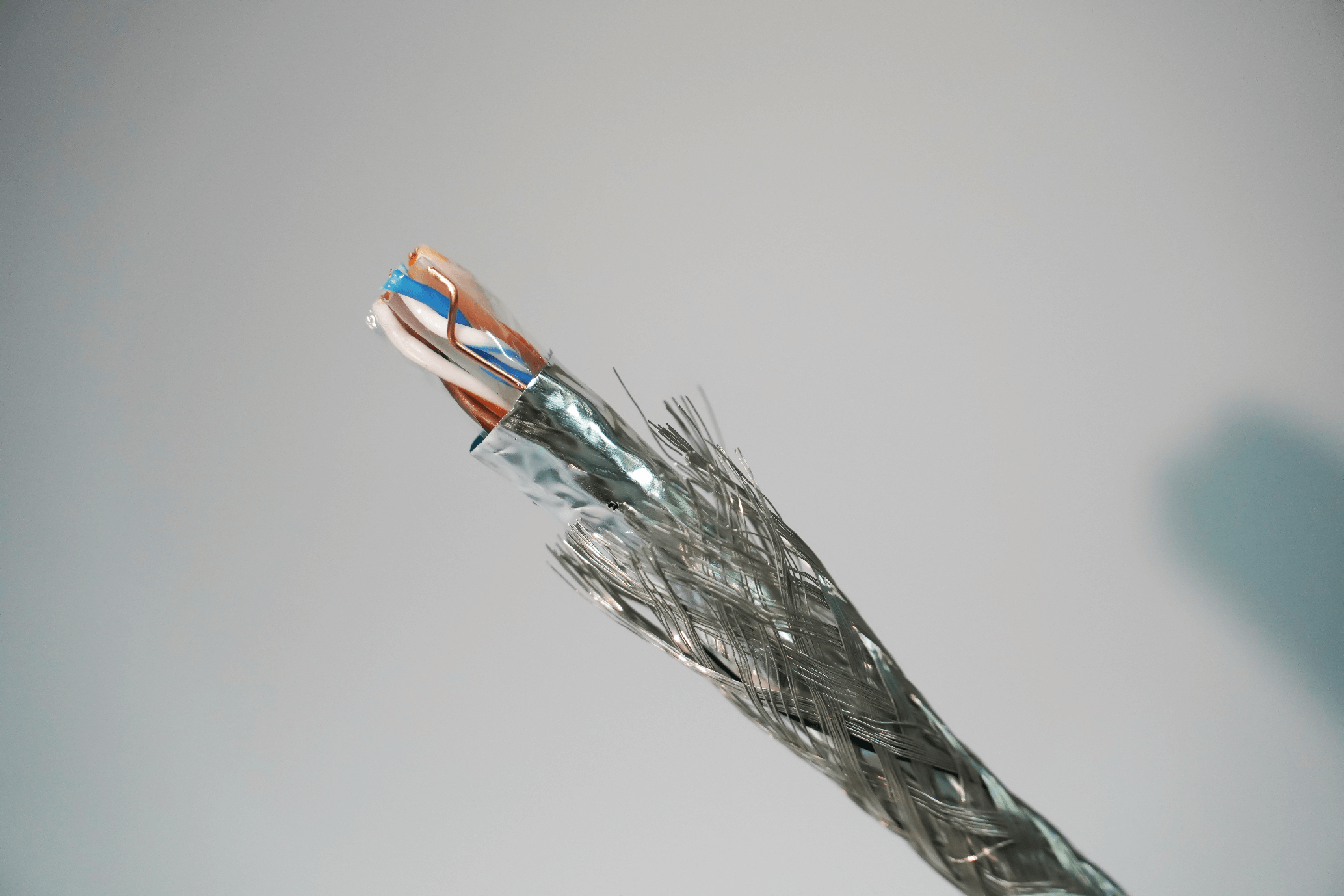

1. LAN Cable Structure

| Component | Specification |

|---|---|

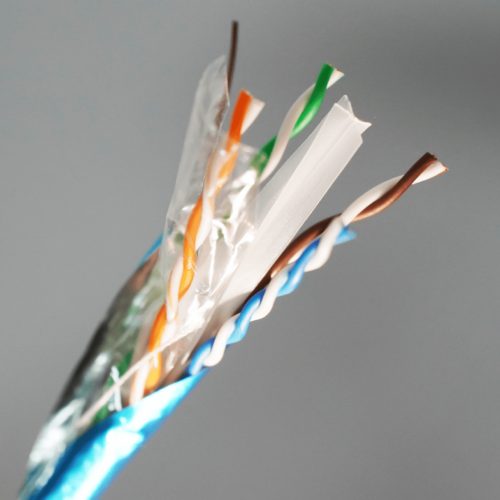

| Conductor | Solid bare copper, 23 AWG (0.57 mm nominal), Class 1 as per IEC 60228 |

| Insulation | High-density polyethylene (HDPE), precision-extruded, color-coded |

| Twisted Pairs | 4 balanced pairs (8 conductors) with optimized lay-length for NEXT control |

| Pair Shielding | Individually wrapped with Al/PET foil, ≥25μm, 100% coverage |

| Overall Shielding | Tinned copper braid (≥60–80% optical coverage), anti-static and EMI-resistant |

| Drain Wire | Tinned copper, 0.4–0.5 mm², ensures consistent grounding continuity |

| Filler (Optional) | PE cross-web spline or central separator (for enhanced crosstalk performance) |

| Jacket | Not included – intended for later extrusion (PVC, LSZH, PE) |

2. Electrical Performance – Category 6 / Class E

| Parameter | Typical Value @100 MHz |

|---|---|

| Characteristic Impedance | 100 ± 15 ohms |

| NEXT (Near-End Crosstalk) | ≥ 55 dB |

| PSNEXT | ≥ 52 dB |

| Return Loss | ≥ 20 dB |

| Attenuation | ≤ 20.9 dB/100m |

| DC Conductor Resistance | ≤ 9.38 ohms/100m |

| Resistance Unbalance | ≤ 5% |

| Propagation Delay | ≤ 535 ns/100m |

| Delay Skew | ≤ 45 ns/100m |

3. Outstanding Advantages

1. Dual-Layer Shielding

Foil on each pair + braided shield offers exceptional protection against EMI/RFI and alien crosstalk

Outperforms F/UTP and U/FTP in electrically noisy environments, such as near HVAC systems, generators, or power lines

2. Precision Crosstalk Suppression

Individually shielded pairs eliminate internal interference

Delivers consistent NEXT/PSNEXT margin even in high-bundle installations

3. Future-Proof Design for Advanced Networks

1000BASE-T and Gigabit applications with full support for PoE/PoE+ (IEEE 802.3af/at)

Compatible with digital video, VoIP, building automation, and AV over IP

4. OEM-Ready Flexibility

Accepts a wide range of outer sheaths:

PVC for general use

LSZH for indoor fire-safe zones (IEC 60332 / CPR Dca–B2ca)

PE for outdoor/underground direct burial

5. High Manufacturing Efficiency

Stable roundness and concentricity for high-speed jacketing

Uniform lay-lengths minimize jacket bulging and improve extrusion line yield

4. Packaging & Supply Format

| Item | Specification |

|---|---|

| Outer Diameter | ~6.3 – 6.7 mm (without jacket) |

| Standard Reel Lengths | 1000 m / 2000 m |

| Packaging | Wooden drums, PE film-wrapped |

| Core Marking | None – designed for post-extrusion branding |

| MOQ | Typically 5–10 km per specification |

5. Applications

OEM cable manufacturing (CAT6 S/FTP with custom branding)

Data center and telecom environments with strict EMI control

Industrial automation, machine-to-machine Ethernet, medical systems

Public buildings requiring CPR-compliant fire-rated LAN cables