ELECTRICAL AND ELECTRONIC WIRES EXTRUSION LINE

1. Application Scope

The Electrical and Electronic Wire Extrusion Line is an advanced continuous-processing system designed for the insulation and optional jacketing of fine-gauge conductors, primarily used in:

Low-voltage electronic wiring

Internal appliance wiring

Automotive cable harnesses

Communication & signal transmission

Control and instrumentation cables

Typical wire types include:

UL-certified wires (e.g. UL1007, UL1015, UL2464), AV/FLRY automotive wires, hook-up wires, H05V-K / H07V-K harmonized wires, and custom PVC/PE/XLPE insulated single-core and multi-core wires.

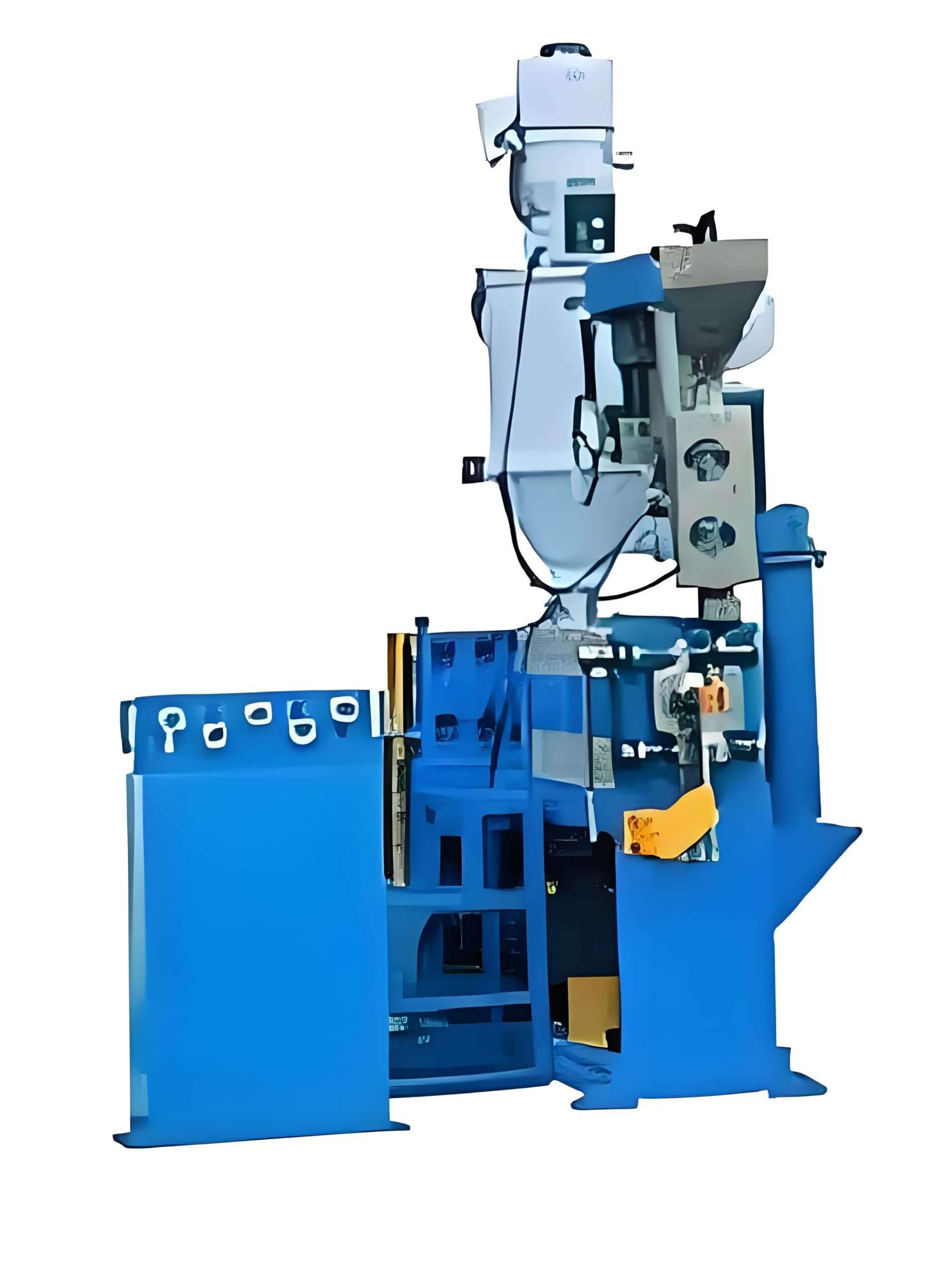

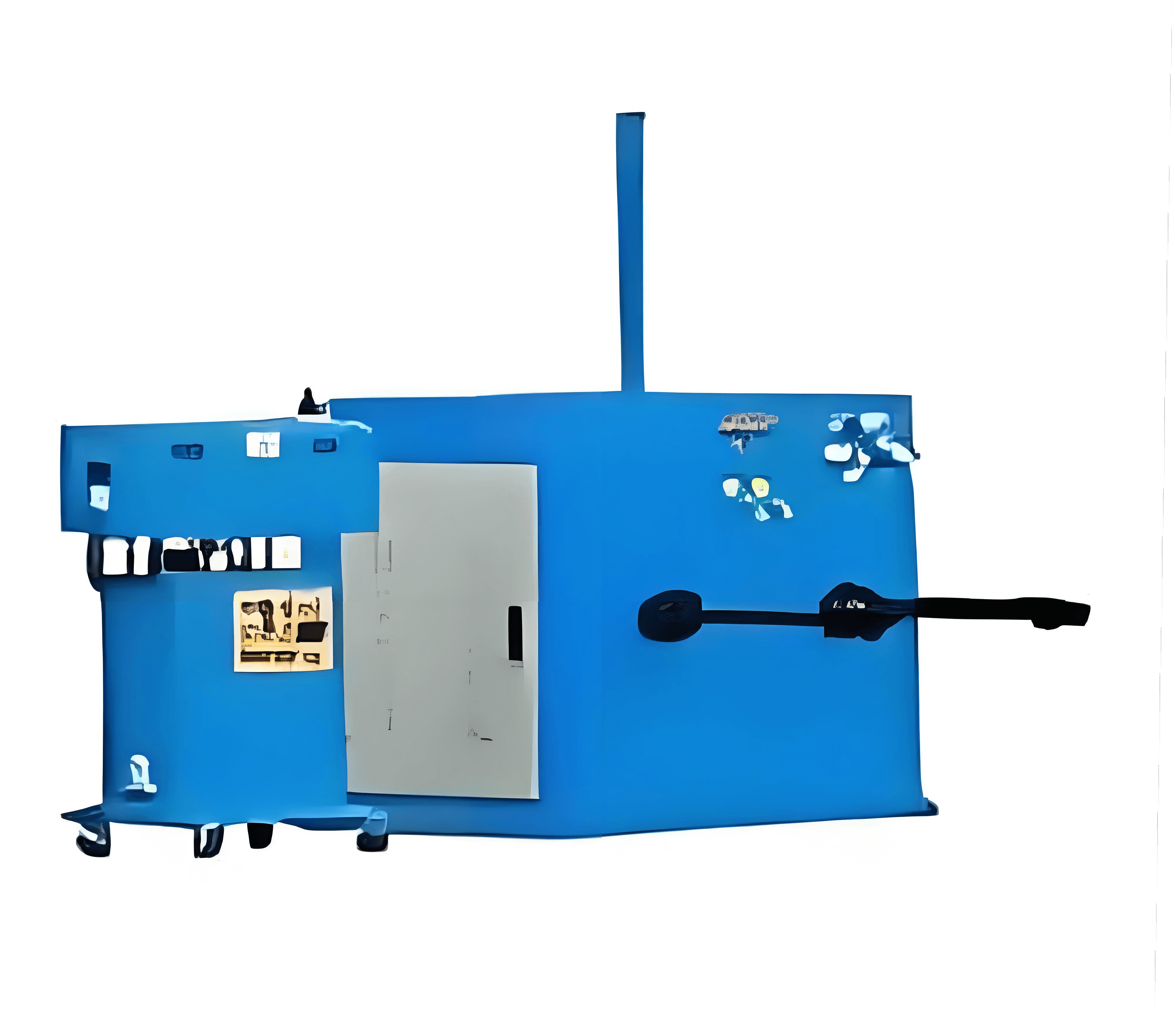

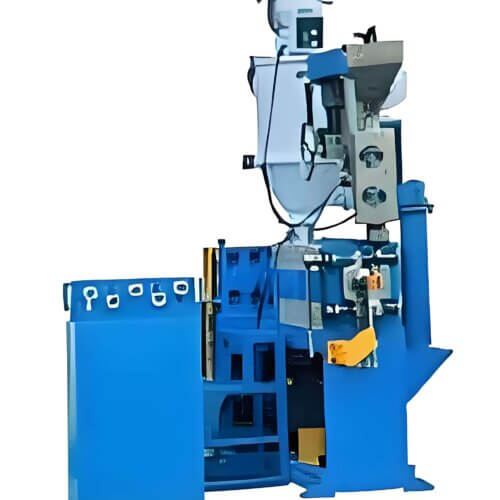

2. Standard Line Composition & Functional Units

| No. | Equipment Unit | Function & Technical Role |

|---|---|---|

| 1 | High-speed Pay-off Stand | Reel sizes: Ø400–800 mm; Constant or dancer-controlled tension feeding; rigid or bobbin-based options |

| 2 | Wire Straightener | Removes torsional strain and ensures concentricity before entering the die head |

| 3 | Conductor Preheater | Induction or infrared heating to improve polymer adhesion and reduce microvoids |

| 4 | Main Extruder | Screw diameters: 30–90 mm; L/D ratio: 25:1 or 30:1; temperature-zoned barrel heating; used for PVC, PE, XLPE, LSZH, TPE, Teflon (optional) |

| 5 | Crosshead Die (Fixed/Adjustable) | High-precision concentric extrusion; adjustable centering; optional stripe co-extrusion |

| 6 | Vacuum or Water Cooling Trough | Stainless steel trough (6–12 m); controlled water circulation system with level, temperature, and pressure control |

| 7 | Laser Diameter Gauge (OD Scanner) (Optional but recommended) | Real-time non-contact laser measurement with closed-loop feedback control for insulation thickness adjustment |

| 8 | High-frequency Spark Tester | 3–15 kV AC/DC spark testing with discharge detection alarm for pinholes and insulation breakdowns |

| 9 | Caterpillar Capstan (Haul-off) | High-grip belt or roller system; servo-controlled pulling speed with synchronized feedback to extruder |

| 10 | Automatic Take-up or Coiler | Available in flange type, single/double spooler, or random/parallel coiling with traversing mechanism; programmable tension and winding modes |

3. Technical Specifications Overview

| Parameter | Specification Range |

|---|---|

| Conductor Diameter | 0.12 mm² – 6 mm² |

| Extrusion Materials | PVC, PE, XLPE, SR-PVC, LSZH, TPE, FEP, etc. |

| Line Speed | Up to 800 m/min (depending on conductor size) |

| OD Control Accuracy | ±0.02–0.05 mm (with closed-loop OD gauge) |

| Extruder Sizes Available | 30mm, 45mm, 60mm, 70mm, 90mm screw diameters |

| Temperature Control Zones | 4–7 heating zones with PID closed-loop control |

| Concentricity Error | ≤ 5% (with precision die & OD monitoring) |

| Typical Output Voltage Rating | 300V, 600V, 1000V (depending on insulation) |

4. Optional Systems for Enhanced Automation & Quality

Co-extrusion head: for skin/stripe, double-layer insulation, or shielding layer integration

Inkjet Printer: real-time marking of cable specs, logos, meter marking, or traceability codes

Gravimetric Dosing System: for automatic material feeding and precise color masterbatch ratio control

Closed-loop OD feedback: real-time OD control with extrusion speed adjustment

PLC + HMI Full Line Automation: integrated recipe management, alarm diagnostics, and Ethernet/Industry 4.0 support

Environmental Compliance: line configurable for RoHS, REACH, UL, VDE, or ISO/TS 16949 certified production

5. Applicable Product Standards

The line can be configured to manufacture wires complying with international standards, including:

UL/CSA (North America): UL1007, UL1015, UL1569, UL2464

JASO / ISO (Automotive): AV, AVSS, FLRY-A/B

VDE / IEC / EN (Europe): H05V-K, H07V-K, H03VV-F

RoHS / REACH / CE certified production support

6. Key Competitive Advantages

High-speed & high-precision production for mass-market electronic wire

Optimized insulation adhesion through precision preheating

Tight OD control and excellent concentricity

Flexible for various polymers (PVC, PE, LSZH, Teflon)

Modular design allows easy upgrade to dual-layer or multi-line configuration