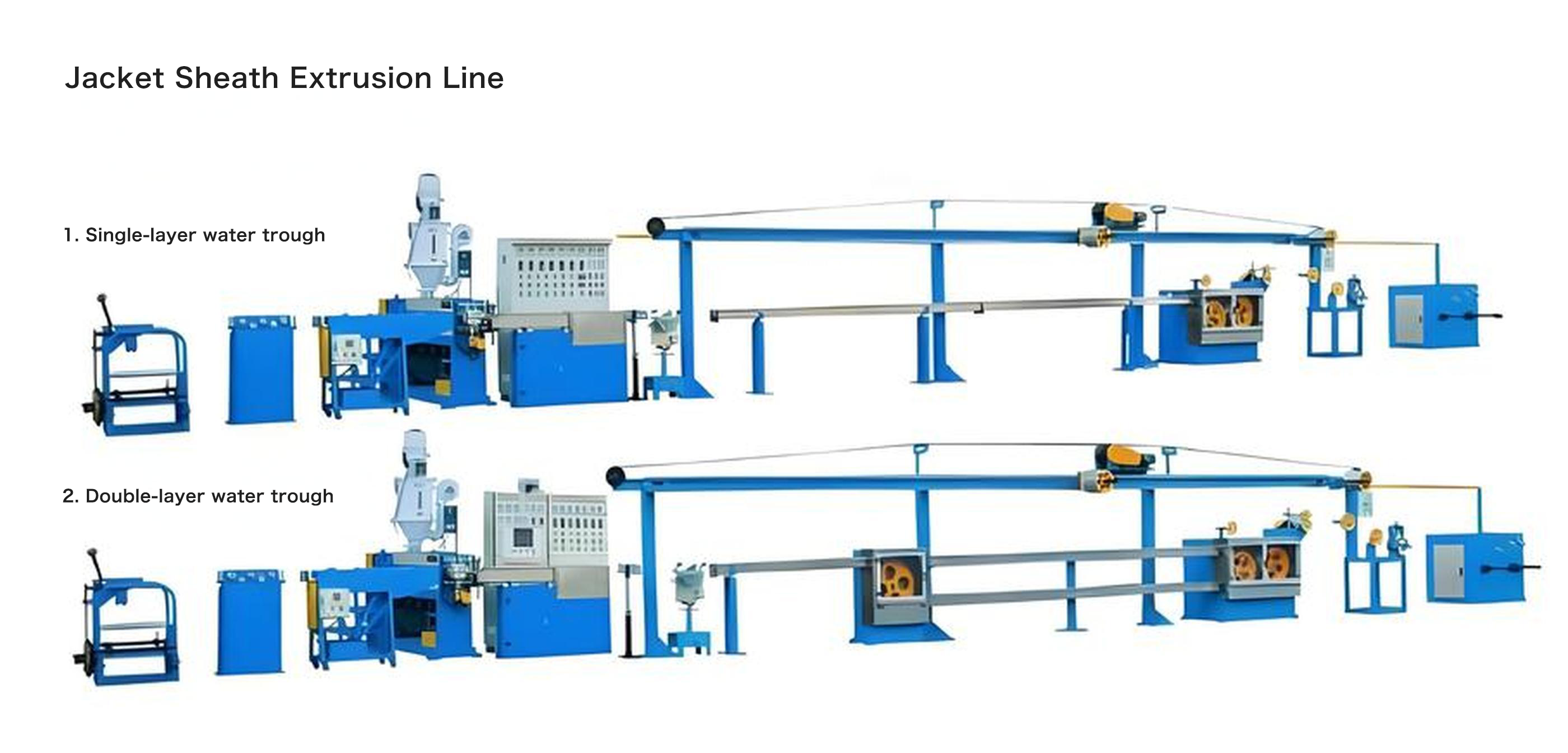

Cat5 CAT6 UTP / FTP / SFTP Lan Cable Making Machine

This LAN cable production line is designed for the extrusion of PVC, PE, and other plastic materials, and is suitable for manufacturing Cat5, Cat6 UTP/FTP/SFTP LAN cables.

LAN Cable Extrusion Machine Specifications

| Model | WRK-50mm | WRK-60mm | WRK-70mm |

|---|---|---|---|

| Screw Diameter | 50 mm | 60 mm | 70 mm |

| Extrusion Output | 70 kg/hr | 100 kg/hr | 150 kg/hr |

| Applicable Wire Diameter | 0.6 – 4.0 mm | 0.8 – 8.0 mm | 1.5 – 12.0 mm |

| Max. Line Speed | 500 m/min | 450 m/min | 350 m/min |

| Capstan Power | 3 HP | 4 HP | 5 HP |