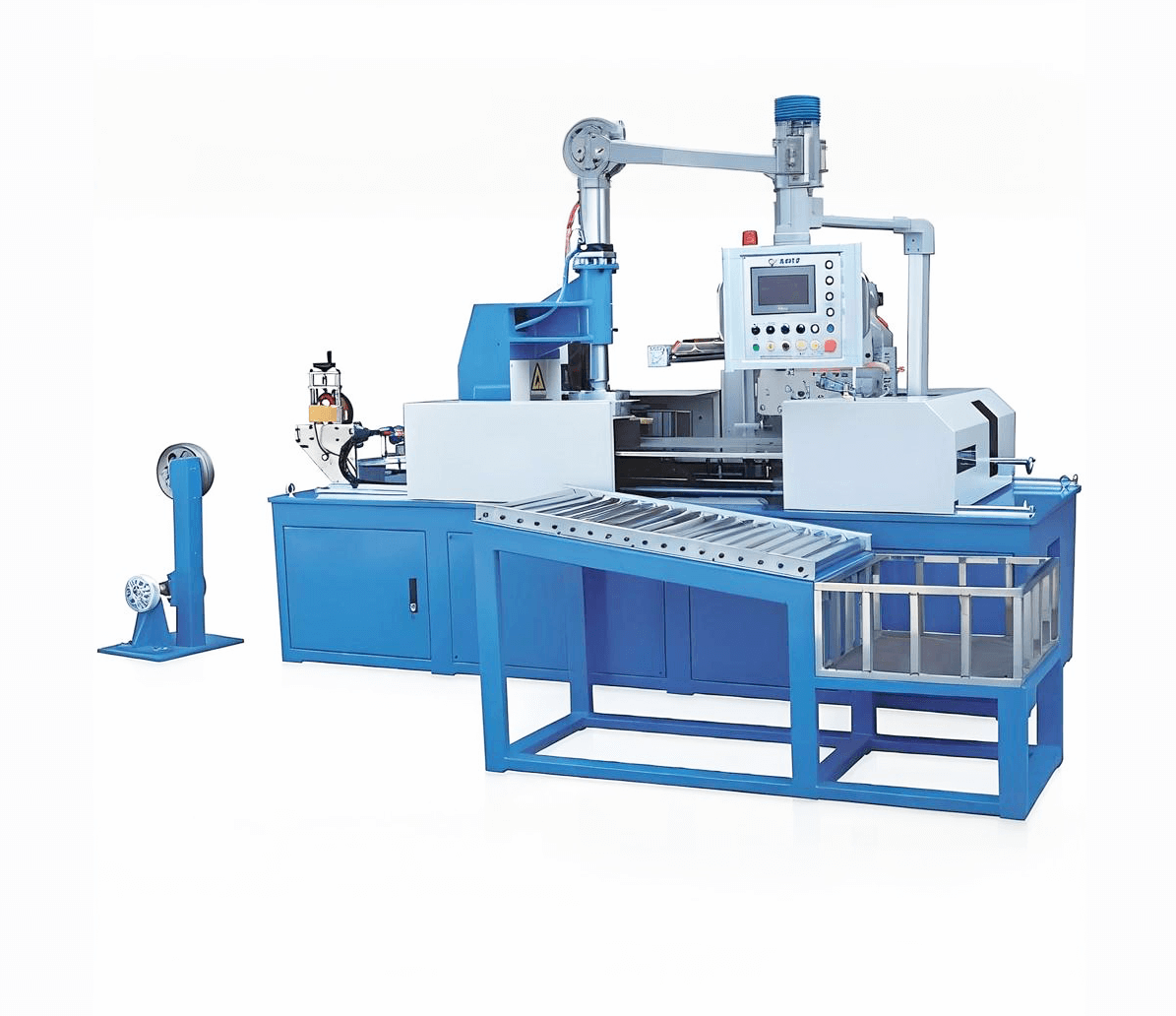

AUTOMATIC COILING AND WRAPPING MACHINE

1. Main Applications

Power cables (e.g., building wires)

Network cables (LAN cables)

Coaxial cables (e.g., RG6/RG59)

Fiber optic drop cables

Plastic hoses and pipes

2. Key Features

| Feature | Description |

|---|---|

| Automatic Coiling | Precisely coils the cable to preset lengths (e.g., 50m, 100m, 305m), with adjustable coil diameter and pitch. |

| Length Measurement | Built-in digital meter counter for high-accuracy length measurement (±0.5%). |

| Cable Tying Function | Optional integration of cable tying system using plastic strap, PE tape, or paper ties. |

| Film Wrapping | Wraps the coil in stretch film, PVC film, or heat-sealable film, providing dust and moisture protection. |

| Touch Screen PLC Control | Human-Machine Interface (HMI) for easy operation, recipe memory, and production monitoring. |

| Automatic Rejection | Removes faulty coils (optional) based on length tolerance or machine alarms. |

| Integration | Can be linked with extrusion lines or payoff systems for fully automated production. |

3. Technical Specifications (Typical)

| Parameter | Value |

|---|---|

| Coil Outer Diameter | 150–400 mm (customizable) |

| Coil Inner Diameter | 100–200 mm |

| Coil Height | Up to 120 mm |

| Cable Diameter | 1.5 mm – 15 mm |

| Coiling Speed | 2–4 coils/min (depends on cable type) |

| Wrapping Film Width | 100–250 mm |

| Power Supply | 380V / 3-Phase / 50Hz |

| PLC & HMI | Siemens / Mitsubishi (custom options) |

4. Advantages

Reduces labor cost and human error

Increases packaging speed and consistency

Enhances product appearance for retail and bulk sale

Supports eco-friendly wrapping materials (e.g., paper or recyclable film)

Enables integration into Industry 4.0 systems for smart factory automation