PLC Control 50Hz Copper Wire Cable Making Machine With PE Material

1. Detail Information

| Usage | Extruding | Voltage | 3phase 380V 50HZ / 60HZ |

|---|---|---|---|

| Warranty | 1 Year, longtime Maitenance | Name | Copper Wire And Cable Extrusion Machine |

| Condition | New | Wire Range | Max.400 |

| Hs Code | 84794000 | After-sales Service Provided | Engineers Available To Service Machinery Overseas |

Highlight | PLC Control wire cable making machine, 50Hz wire cable making machine, 50Hz copper wire making machine | ||

2. Technical parameters for Wire Cable Making Machine

Model | GF-65 | GF-70 | GF-80 | GF-90A | GF-90B | GF-120 | GF-150 | GF-200 |

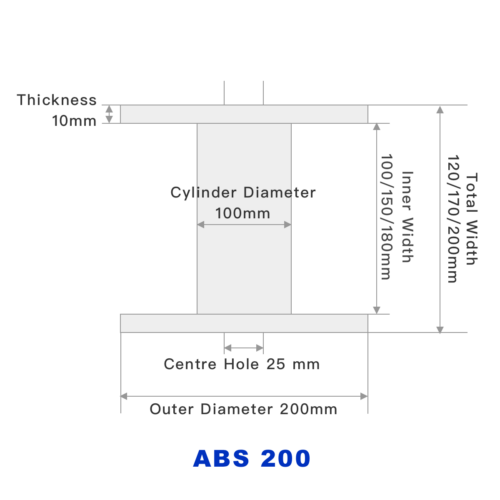

Pay-off Shaft Type | Double-shaft type | 800–1600 mm | 1000–2000 mm | 1600–2500 mm | 1600–3150 mm | |||

Screw Diameter | Ø65 mm | Ø70 mm | Ø80 mm | Ø90 mm | Ø90 mm | Ø120 mm | Ø150 mm | Ø200 mm |

Screw L/D Ratio | 25:01:00 | 25:01:00 | 25:01:00 | 25:01:00 | 25:01:00 | 25:01:00 | 25:01:00 | 25:01:00 |

Max. Extrusion Output | 130 kg/h | 150 kg/h | 200 kg/h | 250 kg/h | 280 kg/h | 400 kg/h | 650 kg/h | 900 kg/h |

Main Motor Power | 25 HP | 30 HP | 40 HP | 50 HP | 60 HP | 70 HP | 100 HP | 150 HP |

Wire Diameter Range | Ø1.2–10 mm | Ø1.5–12 mm | Ø2.0–20 mm | Ø3.0–25 mm | Ø10–40 mm | Ø15–60 mm | Ø30–120 mm | Above Ø40 mm |

Cooling Device | Single layer/Double layers U type | Single layer U type | ||||||

Haul-off Power | 5 HP | 5 HP | 7.5 HP | 7.5 HP | 10 HP | 15 HP | 20 HP | 10 HP |

Max. Line Speed | 500 m/min | 500 m/min | 450 m/min | 400 m/min | 200 m/min | 100 m/min | 60 m/min | 60 m/min |

Take-up Type / Power | Double-shaft bundling | Ø1000–2000 mm | Ø1600–2500 mm | Ø1600–3150 mm | Ø2000–3500 mm | |||

3. Component for Wire Cable Making Machine

| Item | qty. | |

1 | single/double head pay-off | 1set |

2 | Vertical tension dancer | 1set |

3 | Main extruder | 1set |

4 | 2m pre-water cooling trough | 1set |

5 | Diameter gauge | 1set |

6 | Single layer main cooling trough | 1set |

7 | Dual wheel capstan | 1set |

8 | 9m horizontal type cable accumulator | 1set |

9 | 15KV spark tester | 1set |

10 | Meter counter | 1set |

11 | dual reel take up | 1set |

12 | Electrical control system (PLC control) | 1set |

13 | Powder device (opinional) | 1set |

14 | Printer (opinional) | 1set |

15 | Copper preheater | 1set |

4. Key Features

Versatile Material Compatibility: Handles PVC, PE, PU, LSZH, nylon, and other thermoplastics for both insulation and sheath applications.

Customizable Output: Multiple screw diameters and motor powers to match specific production needs.

High-Speed Capability: Line speeds up to 500m/min for small- to medium-diameter wires.

Heavy-Duty Capacity: Larger models support wire diameters up to Ø120mm and extrusion outputs up to 900kg/h.

Efficient Cooling & Haul-off Systems: Ensures consistent insulation thickness and stable production.