Semi-Finished F/FTP CAT6a LAN Cable

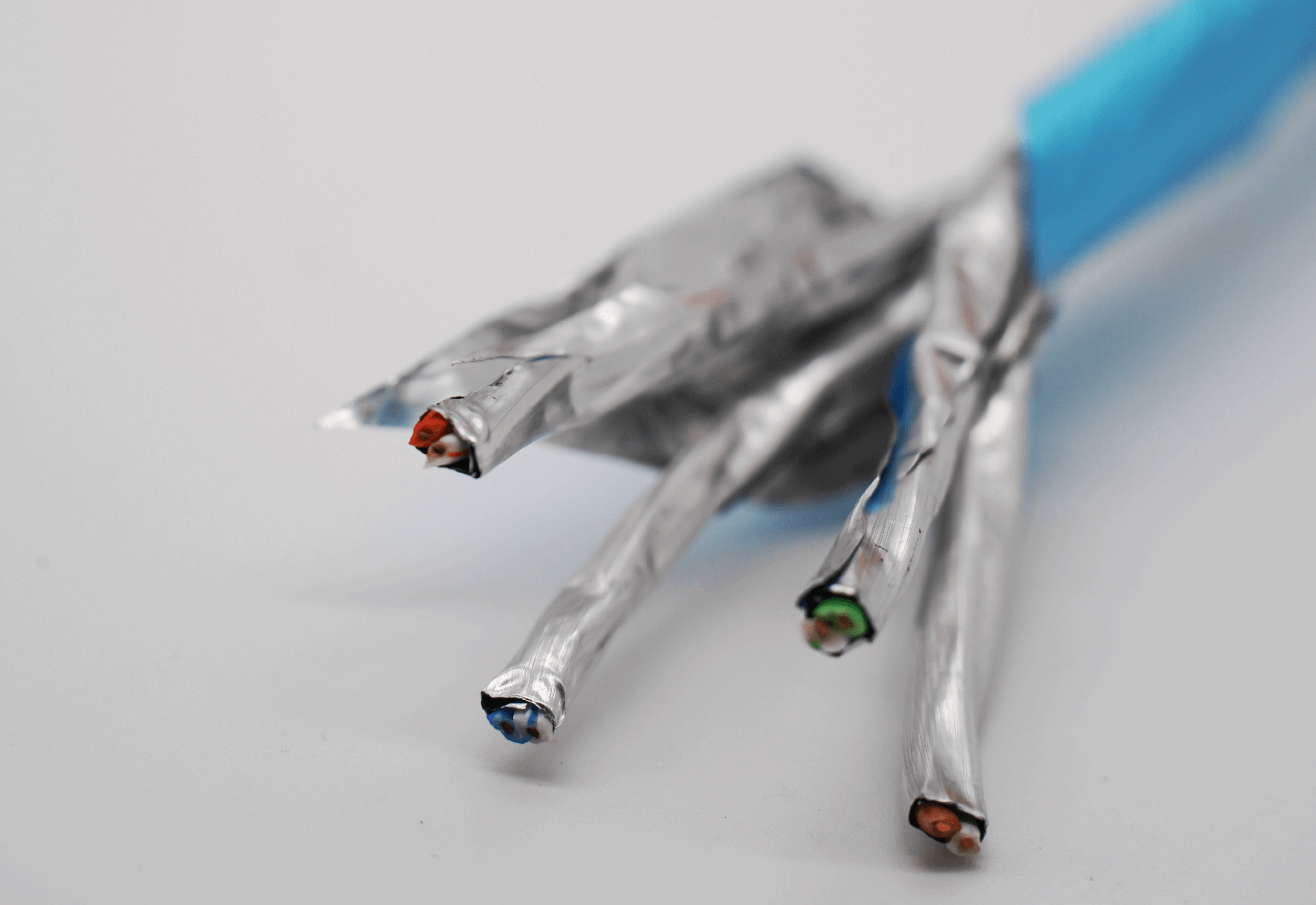

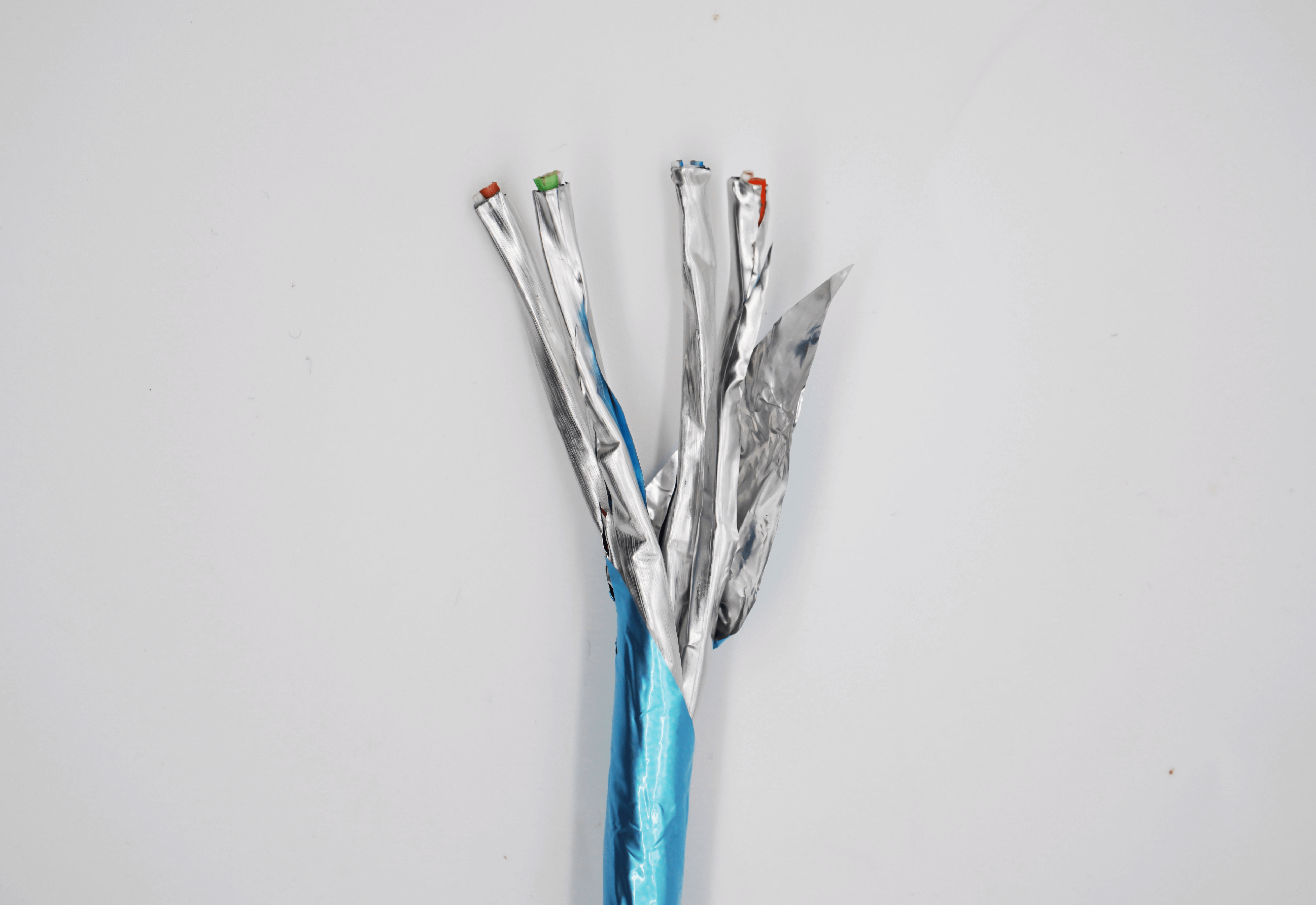

1. LANCable Construction (Core Only – No Outer Jacket)

| Component | Description |

|---|---|

| Conductor | Solid bare copper, 23 AWG (0.57 mm nominal), IEC 60228 Class 1 |

| Insulation | HDPE (High-Density Polyethylene), color-coded to TIA/EIA-568-B |

| Twisted Pairs | 4 pairs (8 conductors total), tightly twisted for crosstalk mitigation |

| Pair Shielding | Each pair wrapped in individual aluminum foil (Al/PET) |

| Overall Shielding | Full-size aluminum-polyester foil wrap enclosing all four pairs |

| Drain Wire | Tinned copper wire, in contact with overall foil, for effective grounding |

| Separator | Optional PE cross-web or spline to enhance NEXT/PSNEXT performance |

| Outer Jacket | Not included (core supplied for jacket extrusion) |

2. Electrical & Performance Characteristics

| Parameter | Typical Value (@100 MHz) |

|---|---|

| Impedance | 100 ± 15 ohms |

| Attenuation | ≤ 21.9 dB/100m |

| NEXT | ≥ 65 dB |

| PSNEXT | ≥ 62 dB |

| Return Loss | ≥ 20 dB |

| DC Resistance | ≤ 9.38 ohms/100m |

| Propagation Delay | ≤ 534 ns/100m |

| Delay Skew | ≤ 44 ns/100m |

Meets or exceeds the requirements of TIA-568.2-D and ISO/IEC 11801 Class EA.

3.Key Advantages

Dual shielding (foil on each pair + overall foil) for enhanced EMI/RFI protection

Improved alien crosstalk suppression, especially important for dense installation environments

Ideal core cable for PoE, PoE+, and 10GBASE-T systems

Enables customized jacket materials and CPR classes (B2ca / Cca / Dca) based on downstream production needs

4.Supply Format

| Specification | Description |

|---|---|

| Core OD | Approx. 6.3 – 6.7 mm (without jacket) |

| Standard Length | 1,000m / 2,000m wooden drums |

| Packaging | Wooden reel with PE film wrapping |

| Marking | Bare core – no printing (for OEM branding) |

| Outer Jacket | Not included (PVC/LSZH/PE to be added) |

5.Application Scenarios

Final assembly into CAT6a LAN cables with LSZH, PE, or PVC sheaths

High-performance data cables for enterprise networks, data centers, and EMI-prone environments

Used in custom shielded LAN harnesses, industrial Ethernet, and PoE deployments

Suitable for CPR-certified cable manufacturing when combined with compliant outer jackets

6. Optional Customizations

Drain wire size (e.g., 0.4–0.5 mm² tinned copper)

Foil material type and thickness (standard 0.025–0.05 mm Al/PET)

Conductor coating (bare or tinned copper)

Optimized twist lay lengths for enhanced NEXT/PSANEXT control

X-shaped central separator (for mechanical structure & electrical isolation)