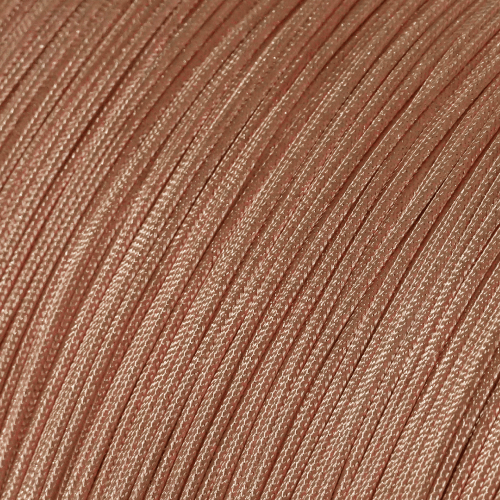

Foamed Insulation Semi-Finished Coaxial Cable

1. Basic Structure

Inner Conductor (Copper or CCA)

+

Foamed Insulation Layer (PE or FEP)

2. Purpose of Foamed Insulation

Reduces dielectric constant for better signal transmission and lower attenuation.

Improves high-frequency performance, suitable for RF, CATV, and broadband signals.

Lightweight & cost-effective compared to solid insulation.

3. Key Manufacturing Process

1) . Conductor Preparation

Copper rod drawing & annealing.

Stranding (for multi-strand conductors).

Surface cleaning for optimal insulation adhesion.

2) . Foamed Insulation Extrusion

Raw material: Foaming-grade PE or FEP with foaming agents.

Physical foaming: Injecting gas (e.g., nitrogen) into the melted polymer.

Chemical foaming: Using chemical blowing agents that release gas during heating.

Control of:

Foam cell size and density.

Insulation diameter uniformity.

Surface smoothness.

Cooling & Sizing: Solidifies insulation and maintains dimensional stability.

Online Testing: Continuous monitoring of insulation thickness and concentricity.

4. Next Processing Stages

Once foamed insulation is completed, the semi-finished product will undergo:

Aluminum foil or copper tape wrapping (shielding).

Braiding: Copper/CCA wire braiding for enhanced shielding.

Jacket Extrusion: PVC, PE, or LSZH outer sheath for protection.

Marking & Coiling

5. Applications

RG Coaxial Cables (e.g., RG6, RG59)

CATV cables

Satellite TV

Broadband internet cables

RF signal transmission