Semi-Finished Coaxial Cable – RG11 CU/48/CCA

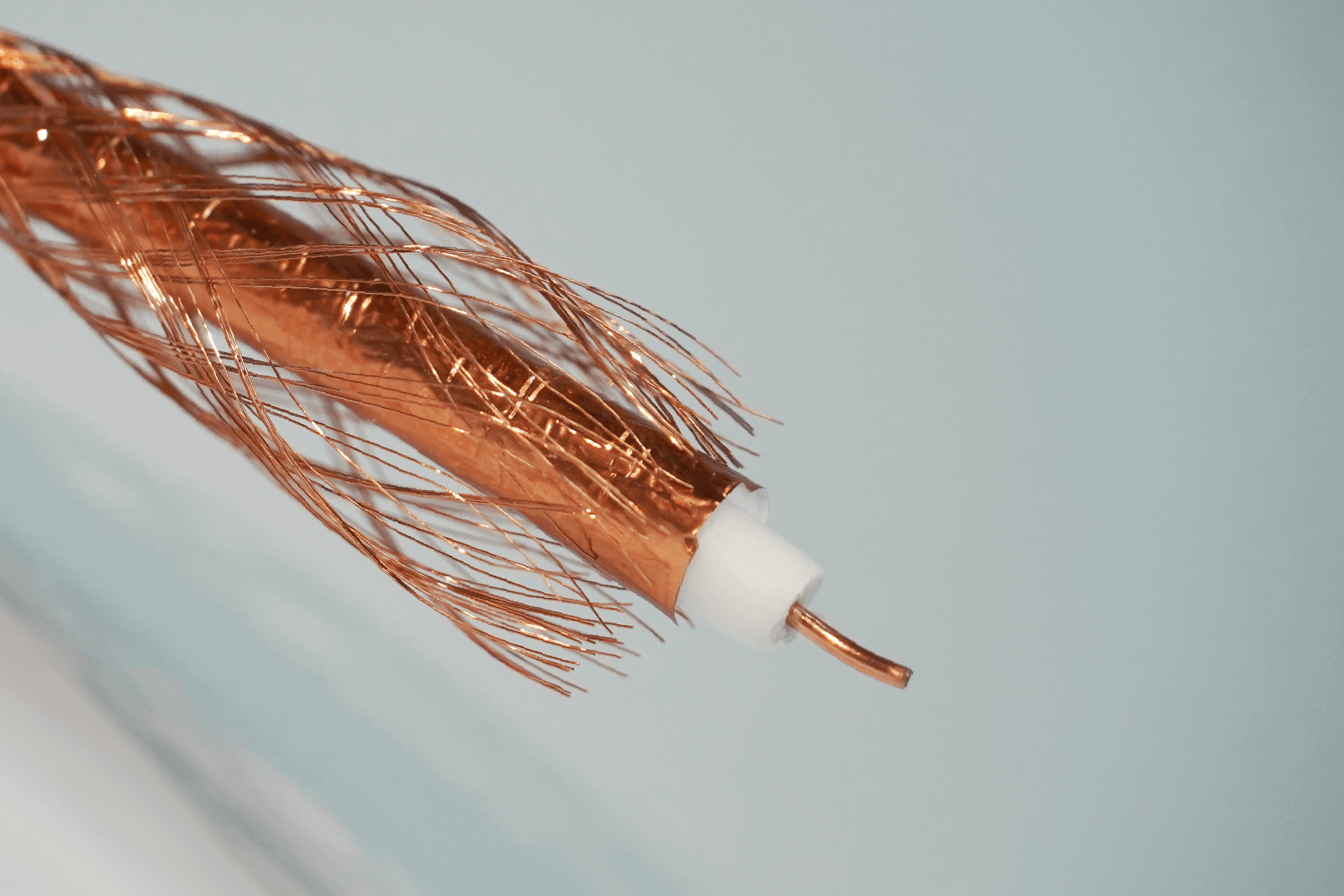

1. Construction Details (No Outer Jacket)

| Layer | Material | Approximate Diameter |

|---|---|---|

| Inner Conductor | Solid Copper (CU) – Ø 1.63 mm (14 AWG) | 1.63 mm |

| Dielectric | Physically Foamed Polyethylene (FPE) | ~7.24 mm |

| First Shield (Foil) | Bonded Aluminum-Polyester Tape (100%) | — |

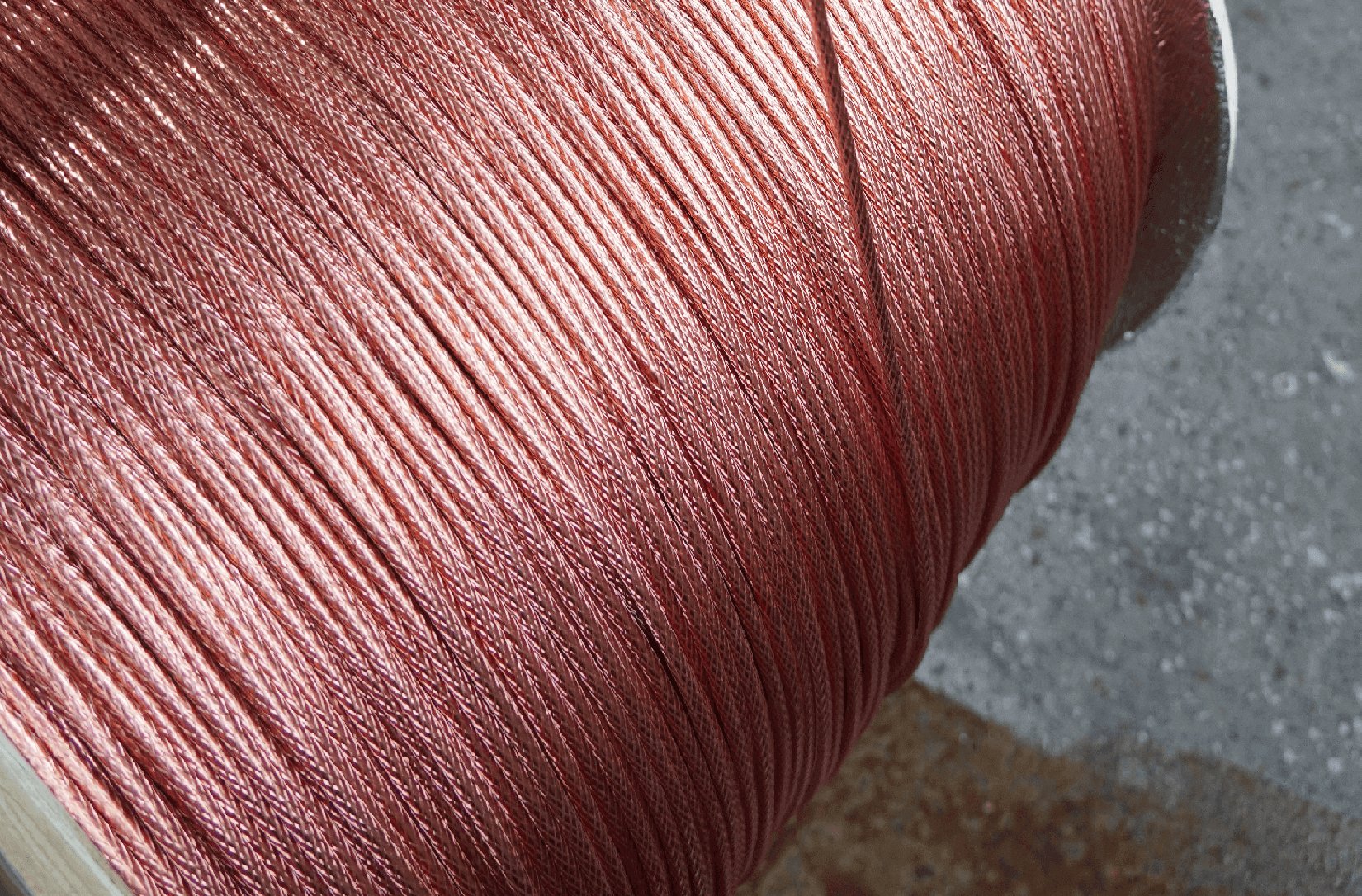

| Second Shield (Braid) | 48 wires of CCA (typically 0.16–0.20 mm) | ~30–35% coverage |

| Outer Jacket | Not present – intended for customization | — |

2. Electrical Performance

| Parameter | Typical Value |

|---|---|

| Impedance | 75 ohms |

| Capacitance | ~53 pF/m |

| Velocity of Propagation | ~85% (due to FPE dielectric) |

| Attenuation @ 100 MHz | ~5.4 dB/100m (depending on braid %) |

| Shielding Effectiveness | Medium (due to 48-wire CCA braid) |

3. Key Benefits

Solid Copper Core: Ensures low signal loss across long cable runs.

48-wire CCA Braid: More economical than 64/96 braid options, suited for non-critical EMI environments.

Semi-Finished Format:

Enables custom jacket application (e.g. PE, PVC, LSZH, UV-resistant).

Facilitates regional compliance or branding for export.

Supports flexibility in assembly (armoring, bundling, etc.).

4. Common Use Cases

Manufacturing of final RG11 coaxial cables for:

CATV infrastructure

Satellite TV systems

Broadband distribution networks

OEM or export-grade customized cables

Projects requiring:

Custom jackets (e.g., for UV, water, or fire protection)

Armored sheathing or burial-ready design

5. Comparison with Other RG11 Semi-Finished Types

| Specification | CU/48/CCA | CU/64/CCA | CU/96/CCA |

|---|---|---|---|

| Braid Density | ~30–35% | ~40–45% | ~60–65% |

| EMI Shielding | Moderate | Good | Excellent |

| Cost Efficiency | High | Balanced | Moderate |

| Signal Performance | Good | Better | Best (among CCA) |