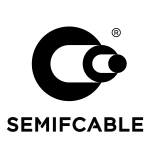

Semi-Finished Coaxial Cable – RG59 CU/48/CCA

Type: 75 Ohm Coaxial Cable Core (No Jacket)

Stage: Semi-finished for extrusion or final assembly

Conductor: Solid Bare Copper (CU)

Shielding: Aluminum Foil + 48-Strand Copper-Clad Aluminum (CCA) Braid

1. Construction Specifications

| Layer | Material | Spec | Function |

|---|---|---|---|

| Inner Conductor | Solid Bare Copper (CU) | Ø 0.81 mm ± 0.01 mm | Excellent signal transmission, low resistance |

| Dielectric | Physical Foamed Polyethylene (PE) | Ø ~3.66 mm ± 0.10 mm | Maintains impedance and reduces capacitance |

| First Shield | Aluminum Foil (Mylar) | 100% coverage | Primary EMI barrier and impedance stabilization |

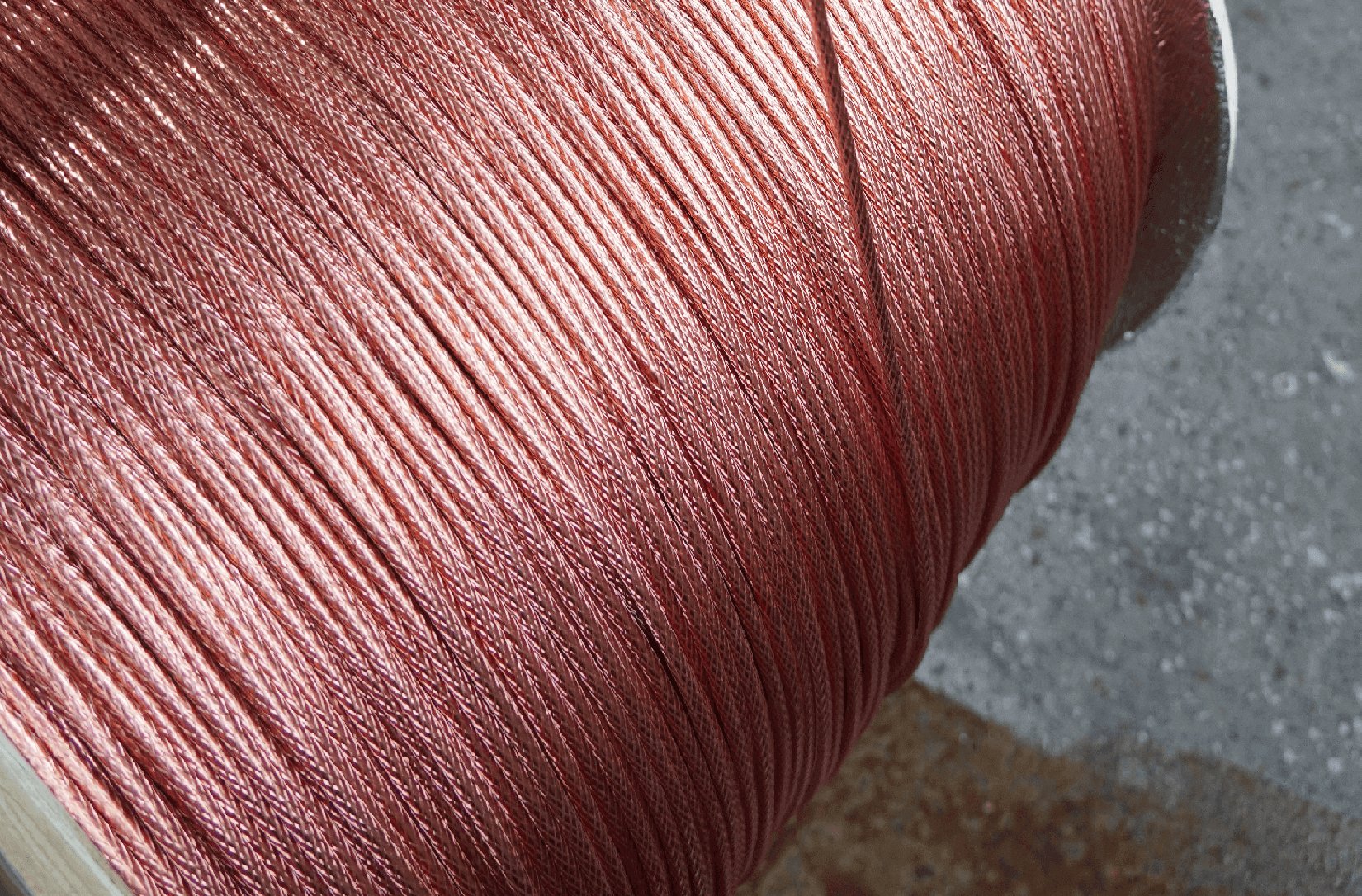

| Second Shield (Braid) | 48 strands of Copper-Clad Aluminum (CCA), Ø 0.12 mm | ~35–45% coverage | Lightweight, cost-saving secondary EMI shield |

| Outer Jacket | Not included | — | To be applied during downstream manufacturing (PVC, PE, LSZH) |

2. Typical Electrical Characteristics

| Parameter | Value |

|---|---|

| Impedance | 75 ± 3 Ω |

| Capacitance | ~53 pF/m |

| Velocity of Propagation | ~85% |

| Attenuation @ 100 MHz | ~6.6–6.8 dB/100m |

| Return Loss | ≥ 20 dB |

| Shielding Effectiveness | ~40–45 dB (dependent on braid quality and density) |

3. Application Scenarios

Analog CCTV systems (standard resolution)

Entry- to mid-level video signal transmission

Budget-sensitive OEM cable production

Short- to medium-distance RF interconnects

4. Post-Jacketing Customization Options

Outer Jacket Materials:

PVC (indoor use)

PE (UV-resistant, outdoor use)

FR-PVC / LSZH (for CPR compliance)

Certifications (optional after final assembly):

CE, RoHS, CPR Eca or Dca (with compliant jacket and production testing)

Branding & Printing:

OEM meter marking, logos, product codes

Packaging Formats:

Supplied on 500m/1000m wooden or plastic reels

Ready for extrusion line input