Semi-Finished S/FTP CAT7 LAN Cable

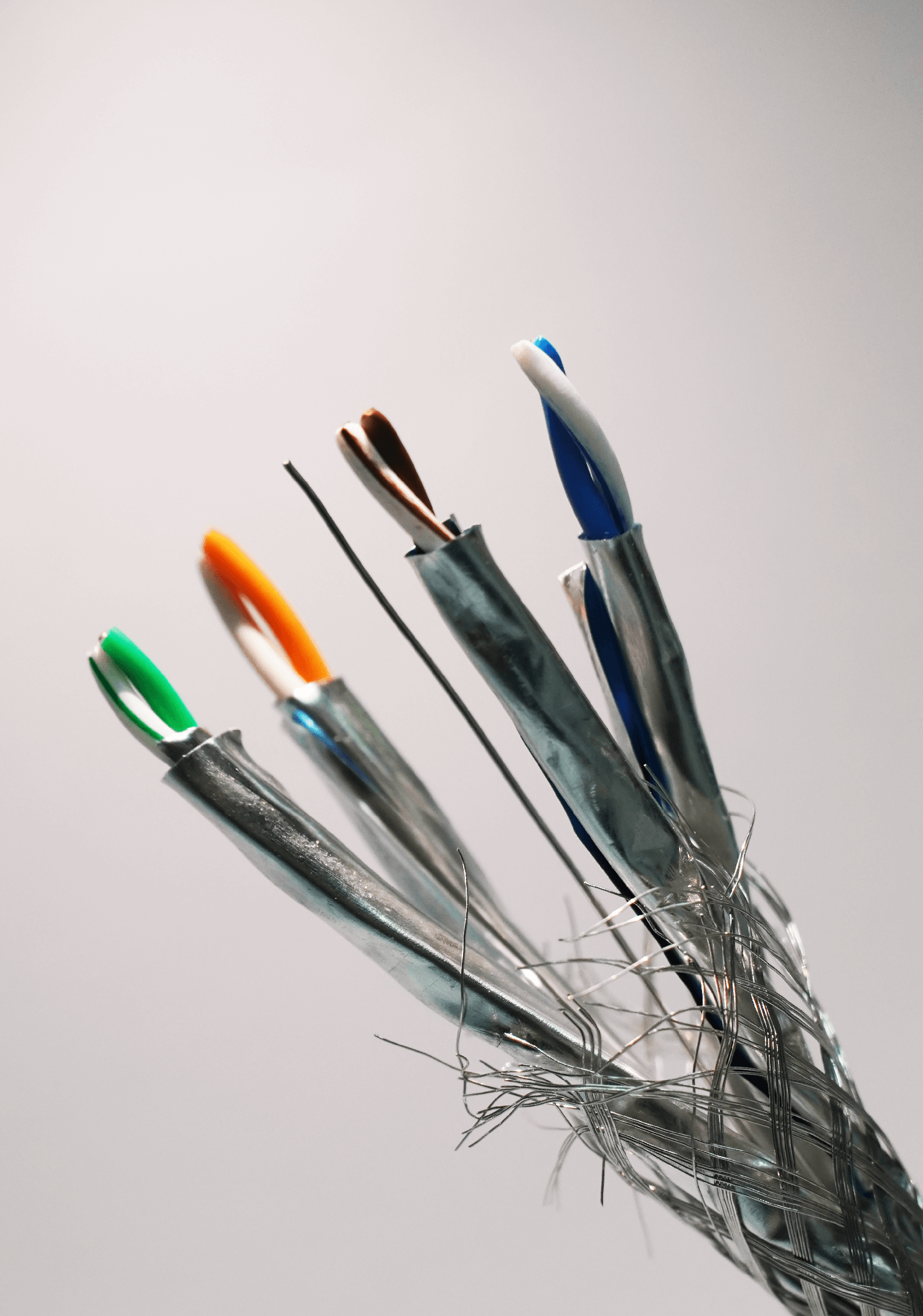

1. Network cable structure

| Component | Specification |

|---|---|

| Conductor | Solid bare copper, 23 AWG (0.57 mm), Class 1 (IEC 60228) |

| Insulation | Foamed polyethylene (FPE) or solid HDPE, color-coded |

| Twisted Pairs | 4 pairs (8 conductors), optimized lay-length for low crosstalk |

| Pair Shielding | Each pair wrapped in Aluminum-Polyester Foil (Al/PET) |

| Overall Shielding | Tinned copper braid, ≥ 70% optical coverage |

| Drain Wire | Tinned copper wire for electrical continuity (optional per jacket design) |

| Separator | Optional PE central filler or non-woven wrapping |

| Outer Jacket | Not included – for OEM-controlled extrusion process |

2. Electrical & Transmission Performance

| Parameter | Typical Value (@600 MHz) |

|---|---|

| Characteristic Impedance | 100 ± 10 ohms |

| NEXT (Near-End Crosstalk) | ≥ 60 dB |

| PSNEXT | ≥ 57 dB |

| Return Loss | ≥ 20 dB |

| Attenuation | ≤ 44 dB/100m |

| DC Resistance | ≤ 9.5 ohms/100m |

| Delay Skew | ≤ 40 ns/100m |

| Propagation Delay | ≤ 530 ns/100m |

Conforms to:

ISO/IEC 11801 Class F

EN 50173-1

TIA-607-C (optional for grounding design)

RoHS, REACH, and CPR-compliant (when jacketed accordingly)

3.Outstanding Advantages

1. Full Shielding for Maximum Noise Immunity

Each pair is individually shielded to eliminate internal pair-to-pair crosstalk

Overall braid shield resists external EMI, making it ideal for data centers, broadcast, and industrial control environments

2. Future-Ready Bandwidth & Speed

Supports 10GBASE-T Ethernet up to 100 meters

Delivers high integrity for data, video, and power (PoE++) simultaneously across demanding backbone or trunking systems

3. OEM Customization Flexibility

Compatible with outer jackets for indoor (PVC/LSZH) or outdoor (PE) environments

Ideal for manufacturing B2ca or Cca CPR-rated cables for the European market

Can be customized with specific twist ratios, drain wires, or enhanced flame-retardant fillers

4. Robust Mechanical Integrity

Thick core structure ensures crush resistance, durability, and stable geometry for high-speed extrusion

Suitable for patch cable production, structured cabling links, or pre-terminated trunk systems

4. Supply Format

| Item | Specification |

|---|---|

| Core Outer Diameter | Approx. 7.5 – 8.0 mm (without jacket) |

| Standard Lengths | 1,000m / 2,000m per wooden reel |

| Packaging | PE-wrapped wooden drums or palletized |

| Print Marking | None – intended for post-extrusion labeling |

| MOQ | 3,000 – 5,000 meters per type |

5. Application Scenarios

Manufacturing of high-grade S/FTP CAT7 LAN cables for:

Data centers and server rooms

Medical, military, or EMI-sensitive facilities

Industrial automation and control systems

Broadcast, audio-visual, or structured media distribution

Integration into shielded modular systems, pre-terminated cable trunks, or OEM assemblies

6. Customization Options

Shield braid coverage (70% / 80% / 90%)

Foil thickness: standard 25 μm, custom up to 50 μm

Drain wire inclusion (size and coating)

Jacket type (PVC, LSZH, PE), CPR class (B2ca, Cca, Dca)

Packaging: Reel length, marking, color coding