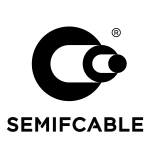

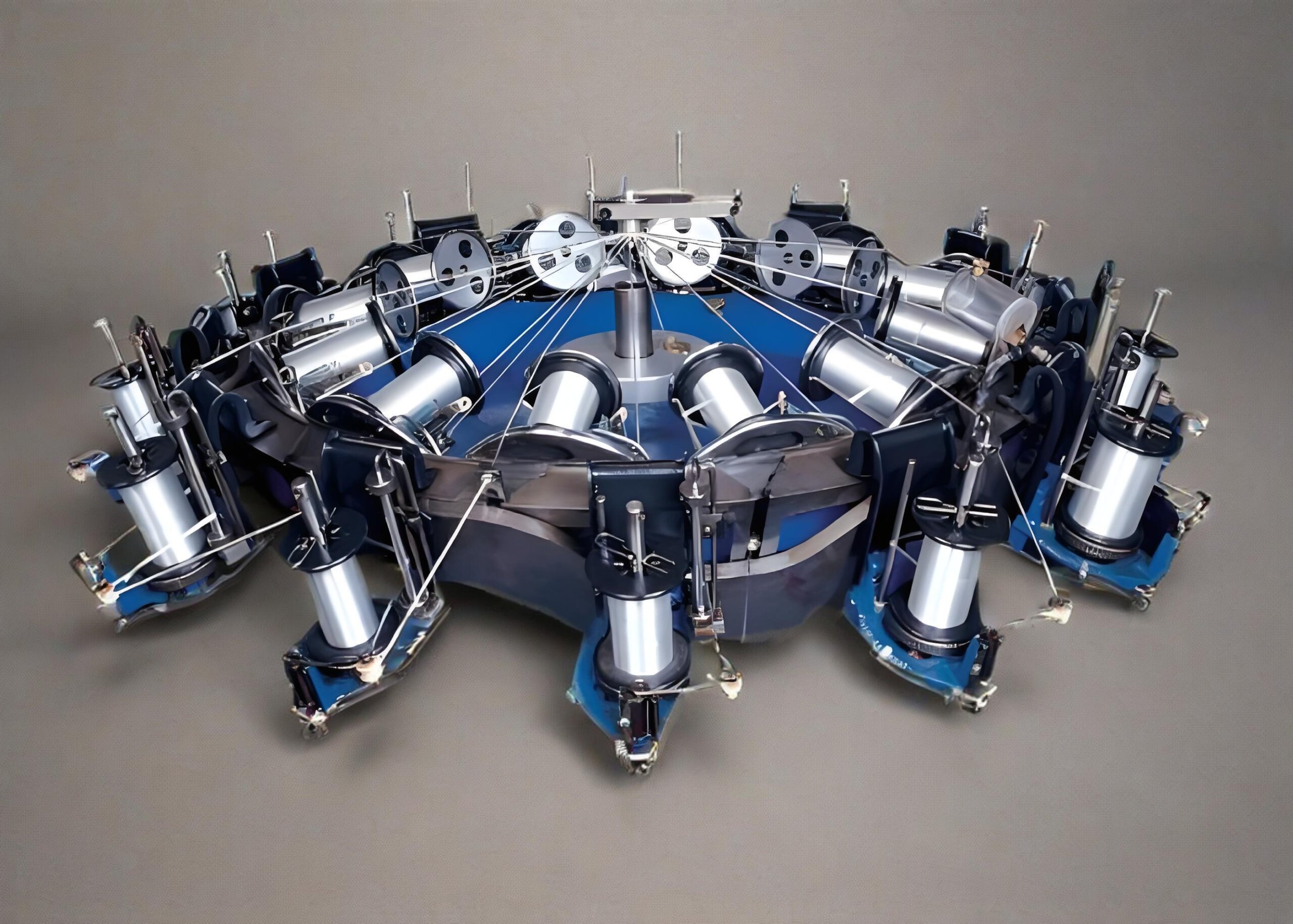

1. Main features include

Braiding method: 2-over-2, with two layers of operation

Braiding direction: Vertical

Spindles: Upper and lower; common in 16AS (16× upper & 16× lower) or 24A variants (12× +12×)

Spindle speed range: Up to 130 RPM (16AS: 10–130 RPM; 24A: 15–100 RPM)

Pitch range: Up to 100 mm (16AS) or 13.3–134.5 mm (24A)

Max cable diameter: For 16‑carrier: 2× 0.08–8× 0.16 mm; for 24‑carrier: up to 24 mm diameter

Power: 3 kW host motor

Dimensions/Weight: Approx. 1500 × 1800 × 2350 mm with ~680 kg weight (varies by model)

2. Highlights & Technical Details

Oil bath lubrication ensures longevity and continuous operation

Sensitive auto-stop system activates upon yarn breakage or run-out, reducing waste and enhancing safety—even unmonitored operations

Variable pitch via gear changes, flexible for adapting to different cable specifications

Frequency‑controlled motor enables stepless speed adjustments and fine control over process rates

3. Typical Variants Compared

| Model | Upper/Lower Spindles | RPM Range | Pitch Range (mm) | Max Diameter | Power | Size (mm) |

|---|---|---|---|---|---|---|

| 16AS | 16 + 16 | 10 – 130 | 0 – 100 | 2×0.08–8×0.16 mm | 3 kW | 1800×1540×2400 |

| 24A | 12 + 12 | 15 – 100 | 13.3 – 134.5 | up to 24 mm | 3 kW | 1500×1800×2350 |

These align with “A‑type” double-layer equipment specs from other manufacturers

4. Suitable Applications

Braiding of metal wires: copper, stainless steel, copper–magnesium alloy, glass fiber, polyester yarn etc.

Ideal for signal cables, coaxial cables, audio cables, and power cable shielding where high output and precision are required

Auto-stop and safety interlocks make it useful for modern automated production lines