TEFLON HIGH-TEMPERATURE EXTRUSION LINE

1. Applicable Fluoropolymers

FEP (Fluorinated Ethylene Propylene)

PFA (Perfluoroalkoxy Alkanes)

ETFE (Ethylene Tetrafluoroethylene)

PTFE (Polytetrafluoroethylene) – for paste extrusion

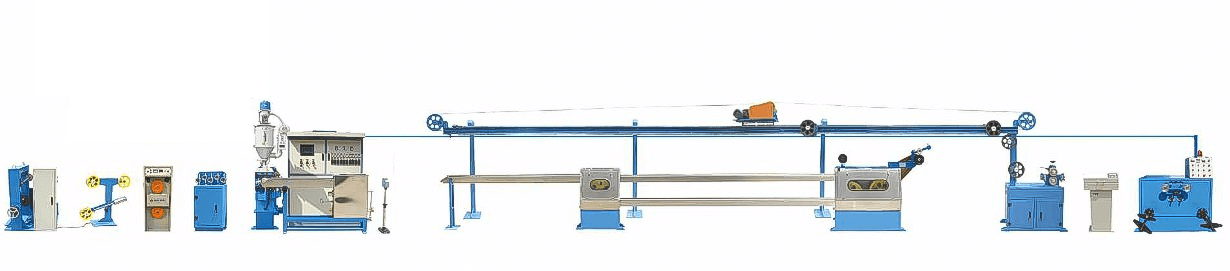

2. Line Configuration (Typical)

| Unit | Description |

|---|---|

| Pay-off Stand | Motorized or dancer-controlled type for smooth feeding of conductor (copper, silver-plated, etc.) |

| Preheating Oven | Removes moisture and preheats conductor for better adhesion of insulation |

| High-Temperature Extruder | Barrel & screw specially treated for fluoropolymer resistance; temperature up to 450–500°C |

| Precision Crosshead Die | Ensures concentric and uniform insulation layer with fine thickness control |

| Curing Oven (Optional) | High-temperature sintering (for PFA or special formulations) |

| Cooling & Water Trough | Multi-section cooling for gradual temperature reduction without internal stress |

| Diameter Gauge | Laser diameter control with closed-loop feedback for consistent insulation thickness |

| Capstan / Caterpillar | Servo motor-controlled pulling to ensure smooth line speed and tension |

| Take-up Unit | Motorized drum take-up or precision traverse take-up depending on application |

3. Key Features

| Feature | Details |

|---|---|

| Temperature Resistance | Extruder & oven designed for continuous operation up to 500°C |

| Chemical Compatibility | Corrosion-resistant components to handle aggressive fluoropolymers |

| Precision Control | Servo-driven systems with PLC & HMI for accurate synchronization |

| Application Flexibility | Supports single-layer, dual-layer, or shielded high-temp cable extrusion |

| Cleanroom Option | For medical-grade FEP tubing and ultra-clean insulation production |

4. Technical Specifications (Example for FEP Cable)

| Parameter | Value |

|---|---|

| Conductor Size | 0.1 – 6.0 mm² |

| Insulation Thickness | 0.1 – 1.0 mm |

| Line Speed | 50 – 200 m/min (depending on size and material) |

| Extruder Size | 30 mm – 65 mm screw diameter |

| Max Temp | 450–500°C barrel zone, 600°C die zone |

| Power Supply | 380V / 3-Phase / 50Hz or customized |

5. Applications

Aerospace & military wiring harnesses

Medical tubing (catheters, probes)

High-temperature sensor wires

Industrial automation & robotics wiring

Automotive engine compartment cables